Employing 85 people and being led by our family of shareholders for five generations. It is the people that create the dedication, innovation and quality supply. With 20% of the staff qualified chemists or Engineers, our focus is on creative solutions to technical problems.

Due to observance of global standards, the company has succeeded in obtaining many certifications as follows:

The beverage industry is one of the most widely used and popular food industry which carbonated beverages have significant share of this market. Of course, carbonated beverage manufacturers face many challenges in increasing and controlling carbon dioxide gas in carbonated drinks, which are aggravated by time and temperature. On the other hand, there are many challenges in the process of producing carbonated drinks that lead to waste of time, water and energy, and ultimately increase production costs.

Stephenson Group has launched a products with name of Sustain to solve the concerns of producers of this industry.

Stephenson Group has pioneered the patented formulation to increase CO2 solubility and extend shelf life of carbonated drinks. The product, named Sustain®, is used as a processing aid in the manufacturing process of carbonated beverages.

Sustain®is a unique non-silicone derived CO2 solubiliser manufactured by Stephenson Group that keeps the fizz in carbonated drinks for longer by increasing the solubility of CO2. The revolutionary new product offers manufacturers and brands the ability to retain carbonation and extend product shelf life – giving consumers carbonated drinks with consistent fizz and flavour.

Sustain® was developed by the Stephenson Group’s Technical Innovations Chemists, in direct response to a problem that has plagued the carbonated drinks market for years: CO2 loss.

“CO2 loss begins during filling, and by the time a drink reaches a consumer it has lost up to 40% of its carbonation. The majority of CO2 loss occurs in PET bottles, where carbon dioxide exits the liquid usually via the headspace and the plastic packaging. More CO2 is lost when the bottle is opened. This often leads to consumer dissatisfaction with the product which is perceived as having gone ‘flat’ within a short space of time.

Drinks brands benefit in the longer term by providing a more pleasurable drinking experience for their consumers, with the drink maintaining the expected level of fizz, improving the product quality and brand perception.

Non-alcoholic beer:

How does it work?

Sustain’s unique patented formulation allows CSD producers to increase CO2 solubility from the moment the drink is filled – which means the drink retains more carbonation until a consumer pours it into a glass and takes their first sip.

Sustain® is a processing aid which makes it easy to improve production efficiencies and reduce costs, all while giving your consumers more of the taste they love. Using an exclusive patented formulation, it keeps the fizz in your carbonated drinks for longer and taste more consistent than ever; by optimising carbonation from the moment the drink is filled, to the very last sip.

Sustain’s unique formula acts as a processing aid during CSD filling by discouraging bubbles from joining and dispersing so quickly – which keeps CO2 solubilised more effectively.

All consumers need to know is that their drink stays fizzy for longer – consistent in fact, from the first sip to the last reducing those tedious complaints on carbonation win-win!

Sustain® is a unique non-silicone derived CO2 solubiliser manufactured by Stephenson Group that keeps the fizz in carbonated drinks for longer by increasing the solubility of CO2. The revolutionary new product offers manufacturers and brands the ability to retain carbonation and extend product shelf life – giving consumers carbonated drinks with consistent fizz and flavour.

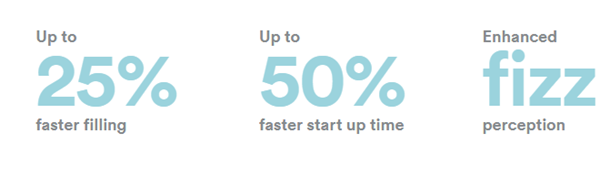

On average, our customers find they can increase filling speeds by around 25%, leading to better and more consistent filling, increased productivity / yields, and fewer rejects. Start-up times can also be massively reduced as the foam caused at filling is now under control

Sustain’s unique formulation controls the excess foam by discouraging bubbles from merging into larger bubbles. This reduces costs by controlling foam in the filling process whilst maintaining the “fizziness” of your drink.

Optimised carbonation level

With Sustain® , because the bubbles are smaller, the poured beverage will be perceived as tasting fizzier, so there is the option of reducing the CO2 level during the filling process without adversely affecting the consumer experience.

Easier to work with:

You can add directly to your concentrated syrup without the need for heating, with minimal stirring. It’s easy to calculate optimum dosage, making the process of switching to Sustain® quick and simple.

With Sustain, up to 20% more CO2 is solubilised within the liquid during the manufacturing process so the drink maintains optimum carbonation for longer. Great news for manufacturers and retailers who can hold more stock for longer – meaning less waste, increased product lifespan and improved profitability.

When poured into a glass, because Sustain® discourages the formation of larger bubbles and foam, your poured drink will be perceived as tasting fizzier by your loyal customers.

Meeting customer demands:

Reduced sugar content is becoming more and more important to CSD customers. Sustain® assists brands in producing drink ranges with sugar substitutes, which would usually cause the drink to foam more in the bottling process. This allows line speeds to remain fast while ensuring your customers are happy!

Because more CO₂ is solubilized in the drink from the start, you can use thinner plastic for your packaging, reducing waste and the pollution it causes. As Sustain® also reduces foam generation, water and energconsumption can be reduced.